charpy impact test composites|charpy impact chart : broker This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test . Resultado da 14 de mar. de 2023 · Clique agora para baixar e ouvir grátis NADSON O FERINHA 2023 CD NOVO postado por ROZIVAN CDS em 14/03/2023, e .

{plog:ftitle_list}

Brasileirão Série A. Tabela. Classificação. Estatísticas. Ranking. Simulador. Regulamento. Histórico.

charpy v notch sample size

Charpy impact test, cement, concrete, mortar, cementitious composites, impact strength See more

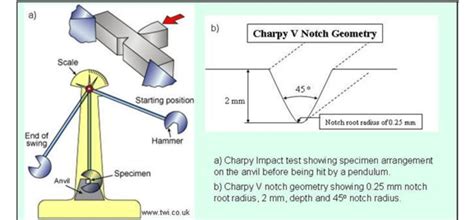

The Charpy impact test relies on the potential energy of a weighted pendulum as shown in Fig. 1. The pendulum is raised to some initial height hi, which is . See moreThough mainly applied to impact testing of metallic and poly-meric materials, the Charpy impact test has seen some use for characterization of cementitious . See more Experimental investigations in a Charpy test rig were conducted in order to identify key parameters influencing the impact damage resistance of composite structures. Using the .

international d282 compression test

charpy impact test sample dimensions

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .

Explore Charpy Impact Testing, a reliable method for assessing material toughness. Learn how it works, key benefits, and how to interpret Charpy impact test results for industrial use. . This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the . Compact Charpy impact testing was employed to investigate the effect of low temperatures on the impact toughness of bulk metallic glass matrix composites (BMGMCs). Samples were fabricated via suction casting and impacted from room temperature down to liquid nitrogen temperature. Unlike monolithic glasses, BMGMCs do exhibit a steep decrease in .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and . Alignment is critical for composite testing applications because composites are anisotropic and generally brittle, as the anisotropy means that the properties and strength of the material differ depending on the direction of the applied force or load. . The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945 .

5.3 For this test method, the energy lost by the pendulum during the breakage of the specimen is the sum of the energies required to initiate fracture of the specimen; to propagate the fracture across the specimen; to throw the free ends of the broken specimen (toss energy); to bend the specimen; to produce vibration in the pendulum arm; to produce vibration or .

Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. Additionally, . A Charpy impact pendulum device was used to test specimens below RT in air. The temperatures (−150 °C, −100 °C, and −50 °C) were controlled by a cooling unit, and the samples were automatically placed in the test position. As the samples were exposed to RT for a few seconds, neglectable heating is expected. In this study, different configurations of epoxy composite laminates that contained thin plies were prepared and characterised for sudden impact load bearing applications. The primary aim of this investigation was to develop a hybrid epoxy-based thin ply composite for aerospace and automotive applications that would be tolerant of high impacts. The impact .

Module 5 - Testing of composites - II D Murali Manohar - Polymer Engineering PEB3213 - Polymer Composites Engineering 8 These two main categories lead to three main types of impact testing. 1. Charpy and Izod impact testing and 2. Drop weight impact testing - low velocity impact testing ASTM D 3763 3. Abstract. Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries. . Charpy Impact Tests of Epoxy Composites Reinforced with Giant Bamboo Fibers. November 2015; Materials Research 18(2):178-184 . specimens for Charpy impact test, with 125 × 12.7 × 10 mm. 3,

international dt466 compression tester

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient .

Impact energy is a measure of the work done to fracture a test specimen. The impact strength of the composites was determined using the edge-wise Charpy impact test according to ASTM D6110-10 (Fig. 5) using a 10.34 J pendulum. When the striker impacts the specimen, the specimen will absorb energy until it yields.

Several researchers have recently employed the Charpy method to characterize the high strain rate mechanical strength of cementitious composites. This paper provides a critical review of existing applications of the Charpy method for impact testing of cementitious composites. Studies have employed various specimen sizes and geometries.

The low-velocity impact behavior of hybrid composite laminates was investigated. The epoxy matrix was reinforced with aramid, glass, basalt, and carbon fabrics using the hand lay-up technique. Different stacking sequences and notch angles were and notch angles considered and tested using a Charpy impact testing machine to study the hybridization and . The objective of this test was to evaluate the energy absorbing characteristics of composite materials at room temperature using the Charpy impact method [6, 11, 12]. For the Charpy test .The fibers were press molded with a orthophtalic polyester resin mixed with the proper hardener and set to cure for 24 hours at room temperature and pressured in the mold up to 5 tons. Specimens were test in a charpy pendulum. The results showed increase in the absorbed impact energy with higher amount of incorporated fiber. Charpy impact strength is significantly affected by the interfacial bond strength, by extension the interlaminar shear strength (ILSS), which is controlled by fiber surface treatments and manufacturing processes [12], [13], [19].The fracture initiation energy during Charpy impact testing increases with increasing ILSS, and displays a minimum when a critical value of ILSS .

CHARPY IMPACT TEST OF POLYESTER MATRIX COMPOSITES REINFORCED WITH SHORT MALLOW AND PIASSAVA NATURAL FIBERS (Atena Editora), 2023. In the contemporary world, natural lignocellulosic fibers (NLFs) reinforced polymer composite materials are of great interest owing to their eco-friendly nature, lightweight, life-cycle superiority, . The Charpy impact test was performed on sisal fibre without filler, sisal fibre with graphene 2% and 4% filled composites. The Charpy impact testing equipment was used for testing, according to the V-shaped notch. The sisal fibre epoxy composite had an impact strength of 2.8 J. The impact strength of a sisal fibre epoxy composite containing 2% .

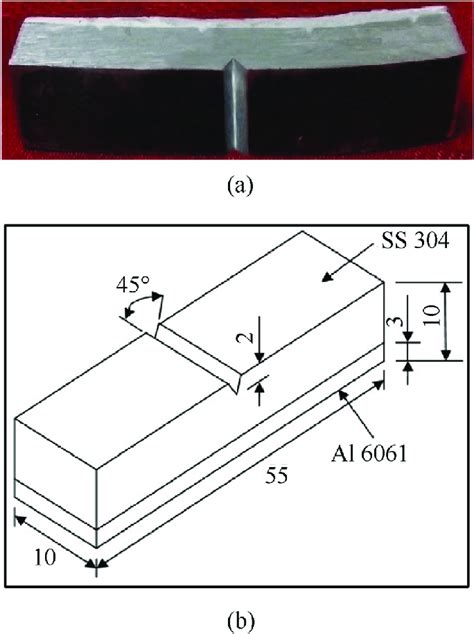

DOI: 10.1016/J.COMPSCITECH.2007.10.008 Corpus ID: 135751098; Charpy impact tests on composite structures – An experimental and numerical investigation @article{Hufenbach2008CharpyIT, title={Charpy impact tests on composite structures – An experimental and numerical investigation}, author={Werner A. Hufenbach and F. Marques .DOI: 10.1016/J.JMRT.2018.03.008 Corpus ID: 84840384; Charpy impact test of epoxy composites reinforced with untreated and mercerized mallow fibers @article{Nascimento2018CharpyIT, title={Charpy impact test of epoxy composites reinforced with untreated and mercerized mallow fibers}, author={Lucio Fabio Cassiano Nascimento and . The composite thus formed was allowed to cure for 24 h at room temperature. The plates of each composite were then cut according to the direction of fiber alignment in bars measuring 10 × 125 × 12.7 mm were used as basis for preparation of test samples Charpy impact test according to ASTM D256 [18,19,20].

In this study, compact Charpy impact testing was used to investigate the effect of processing history and dendrite morphology of bulk metallic glass matrix composites (BMGMCs) on impact toughness .Charpy impact test The specimens used in the impact test are of matic shape (80x15x4), with a lateral notch of the SEN type (single edge notch) as illustrated in Fig specimens were cut from 300x210 mm Low velocity impact can be divided into several types of evaluation. Charpy and Izod impact testing are two types of testing that mostly used by the industry as it was known as an economical quality control method. In this short review, previous studies on the charpy and izod impact testing on natural fibre composites will be discussed. Plates of each composite were then cut, according to the direction of alignment of the fibers, into bars measuring 120 × 12 × 10 mm, which were the basis for making Charpy specimens for impact test as per ASTM D256 standard, according to the scheme shown in Fig. 2.

charpy impact test sample

WEBLarissa Borges. Click to watch more videos like this. onlyfans.com. Get full video. 60 / 0. Favorite. Comments 9. About. Related Videos From Larissa Borges. 03:08. horny .

charpy impact test composites|charpy impact chart